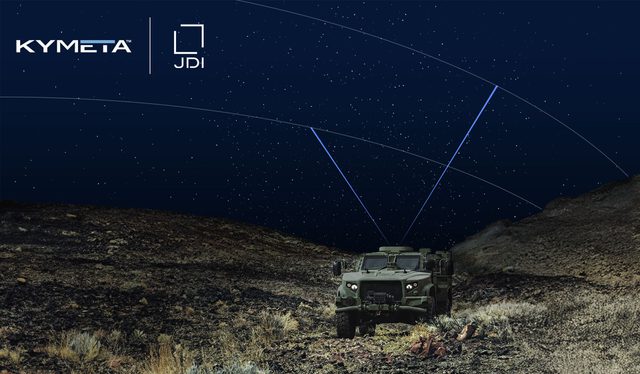

The SATCOM industry is experiencing an unprecedented period of investment and growth resulting in the emergence of new and unique requirements. The surge of new capabilities ranges from high throughput satellites in geostationary orbits (GEO) to the launching of low Earth orbit (LEO) mega-constellations. Simultaneously, mobility has become the key to survivability for DoD. The resulting requirement from this rapid growth is for an affordable, fullduplex terminal with the agility to switch between GEO and LEO in a form factor and power requirement that supports mounting on a range of military vehicles.

Kymeta conducted an extensive literature review to explore options to meet these emerging requirements. The review revealed that traditional phased arrays are unable to produce affordable terminals without making significant functionality trade-offs, such as fixed polarization, half-duplex operation, reduced scan range, and limited bandwidth. Several examples exist of attempts at shared aperture antennas; however, none of the approaches surveyed can meet all the necessary requirements. Attempts to achieve all requirements drive up cost and power consumption beyond a reasonable threshold.

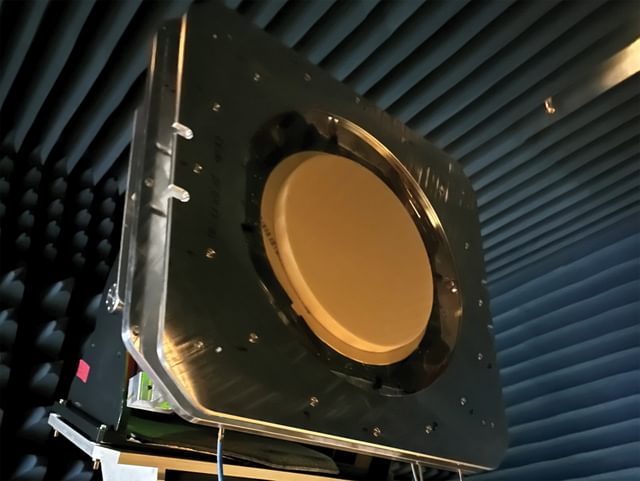

Kymeta takes a different approach by combining the low-cost traditional RF chain with a metamaterial aperture to form a full-duplex terminal. Kymeta’s unique liquid crystal (LC) metamaterial controls the passage of RF energy in a way that determines the beam azimuth, elevation, and polarization. The 60,000 elements that populate the aperture are software controlled, providing the agility to switch from linear polarization required by GEO satellites to circular polarization inherent in LEO satellites – with no additional requirements in the aperture. Because Kymeta’s passive elements can be spaced more closely than phased array elements, both transmit and receive elements are interleaved across the entire face of the aperture.

Kymeta’s technology is enormously complex to create constructive and destructive interference in 3 dimensions and two directions – transmit and receive.

For a layman’s example, Kymeta’s approach can be likened to the Fountains of the Bellagio Hotel & Casino Las Vegas. All the nozzles of the fountain are present—just like our LC elements are present on the aperture. The pressurized water is analogous to RF energy provided by the RF chain. Software controls the release of water through different nozzles to form

different patterns.

Similarly, Kymeta’s software controls the passage of RF energy through the elements to form a beam with the correct azimuth, elevation, and polarization. A change in software can provide an entirely different show with no requirement to modify the hardware.

Kymeta’s liquid crystal-based technology has been so effective that the Kymeta™ u8 terminals enjoy type approval for operation with 15 different GEO satellite service operators (SSO) as well as OneWeb’s LEO constellation. Software updates the modulation pattern on the metasurface, and the LC elements support the forming of an entirely new beam in less than 4 milliseconds – a requirement to operate on LEO with a single antenna. Kymeta’s next generation technology is based on varactor diodes to offer better efficiency, faster switching speeds, and improved performance.

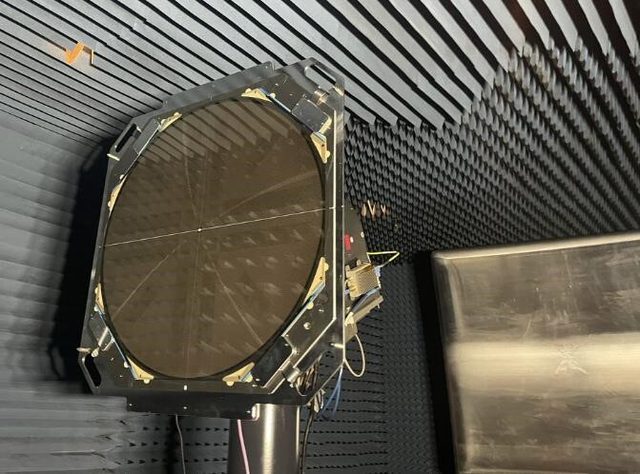

The first proof of concept (POC) is a full-sized Ka-band varactor-based aperture that revealed improved performance across all scan angles and beam forming speeds less than 1 millisecond. This improved performance offers opportunities for meeting DoD’s needs in ways that phased array technology could never consider.

Kymeta’s currently available technology operates in Ku-band on GEO and LEO constellations. With the shift to varactor technology, Kymeta will enter the Ka-band GEO/MEO/LEO space. The improved performance of the varactor technology could also enable interspersing of Ku- and Ka-band diodes to produce a true multi-band, multi-orbit, multi-beam, fullduplex terminal capable of operating across all orbits. Finally, because Kymeta’s technology follows the flat-panel display industry with LCD now and mini-LED (varactor) next, we can access the display industry’s commercialized high-volume pick and place machines—capable of 30,000 die transfers per hour—to manufacture the antenna aperture at scale. The resulting product is reasonably affordable, technologically feasible, and operationally distinct from any other solutions— making the Kymeta Osprey™ u8 a valid course of action for meeting DoD’s rapidly emerging requirements.

To learn more about Kymeta’s technology, click here to explore our technical papers.